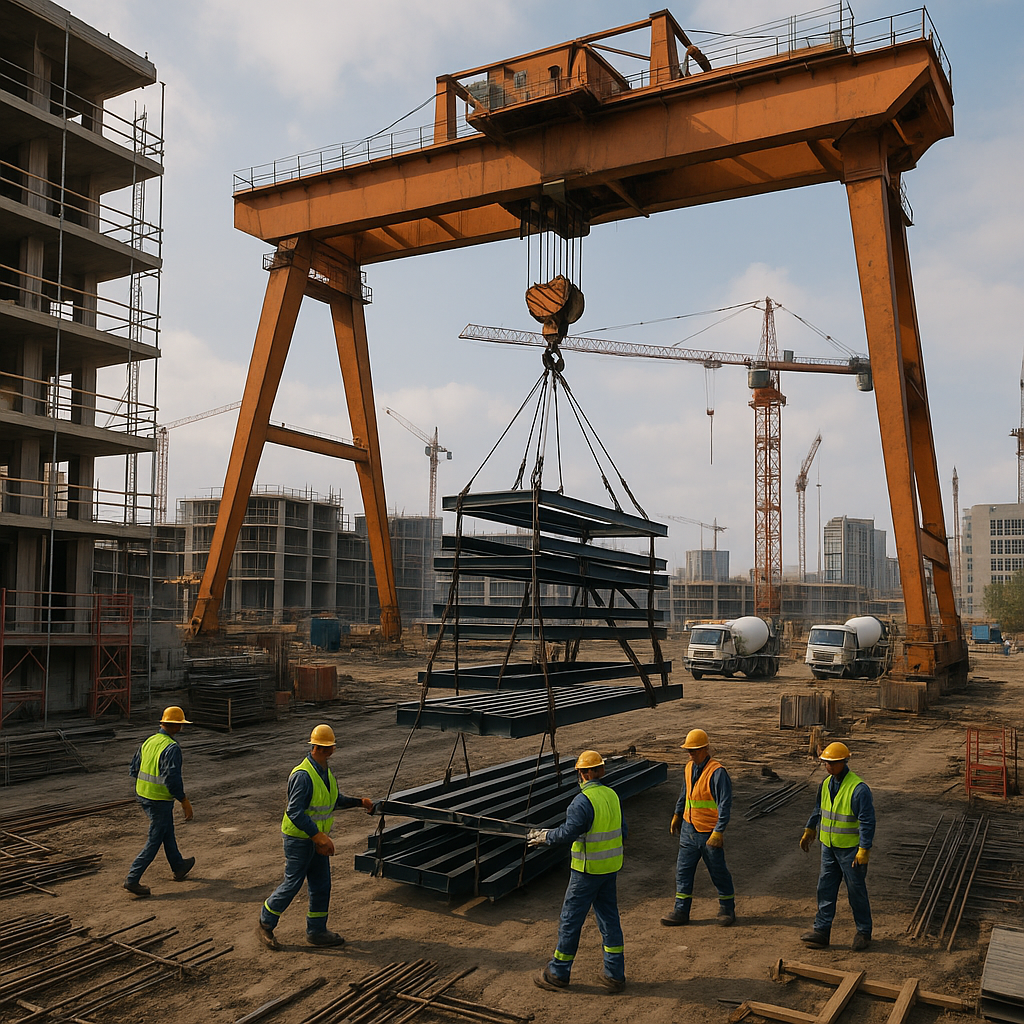

Semi Gantry Cranes

Semi Gantry Cranes are also known as single-leg cranes which are used in specified limited working area. These cranes don’t require runway support on both sides. One end carriage of a semi gantry crane travels on the regular gantry rail while the opposite end-carriage travels on a rail mounted on the ground. Moreover, these can be used for both indoors and outdoors. Semi Gantry Cranes are available in capacities up to 30 Ton.

At its core, a Semi Gantry Crane offers the same material handling efficiency as a full gantry crane but with a smart space-saving design. With one side supported by a traditional gantry runway and the other by ground-level rails, this crane design reduces structural needs and installation costs. It’s ideal for facilities that face spatial constraints or have partial building support, allowing for optimized usage of both floor and overhead space. These cranes are typically installed in industrial workshops, warehouses, and outdoor yards where a full gantry setup isn’t practical or cost-effective.

Key Features of Our Semi Gantry Crane

Konex Material Handling Systems manufactures semi gantry crane with durable components and flexible design specifications to meet your exact site needs.

- Capacity: Available up to 30 Ton

- Adjustable Span: Custom span options for tailored workspace coverage

- Leg Design: One-leg structure to reduce infrastructure requirements

- Hoisting System: Equipped with high-efficiency wire rope or chain hoists

- Build Quality: Heavy-duty structural steel construction with corrosion-resistant paint

- Drive System: Dual-speed or VFD-controlled motors for precise movement

- Control Options: Pendant, radio remote, or cabin controls based on your needs

Top Benefits for Industrial Buyers

Choosing a semi gantry crane from Konex brings clear functional and financial advantages:

- Cost-Effective Setup: No need for full-length gantry rails on both sides

- Space Optimization: Ideal for tight or asymmetrical workspaces

- Indoor & Outdoor Use: Designed for flexible environments

- Reduced Civil Work: Minimal column or beam support required

- Simple Ground Rail Installation: One side runs smoothly on a flat ground track

- Custom Fabrication: Built for your operational dimensions and duty cycle

Applications & Industrial Use Cases

Semi gantry cranes are widely used across industries for intermediate lifting tasks, part transfers, and workspace integration.

Common application areas:

- Fabrication and assembly workshops

- Heavy component transfer zones

- Industrial warehouses and storage areas

- Shipyard semi-covered facilities

- Infrastructure project sites

- Open yards with limited overhead runway options

Industries We Serve

Konex material handling cranes are trusted across industries for precision, safety, and adaptability.

Industries we serve include:

Why Choose Konex as Your Semi Gantry Crane Manufacturer?

With over a decade of experience in the Indian material handling sector, Konex Material Handling Systems LLP, based in Ahmedabad, offers precision-engineered gantry cranes tailored to Indian industrial needs.

- In-House Design & Manufacturing: Ensures consistency, faster delivery, and full quality control

- Make in India Compliant: Built as per Indian Standards (IS) and global norms

- Experienced Engineering Team: Deep knowledge of structural layouts and custom needs

- Installation & Commissioning Support: On-site service and consultation available

- Reliable After-Sales Service: Long-term technical support and easy spare parts availability

We’re a trusted name among semi gantry crane manufacturers in India, delivering projects across sectors nationwide.

Customization Options Available

At Konex, we provide fully tailored semi gantry crane solutions. Every crane is engineered to match your unique layout, load type, and operational duty class.

You can customize:

- Crane Span and Height of Lift

- Load Capacity (up to 30 Ton)

- Crane Travel Speed and Lifting Speed

- Control Mode (manual, pendant, remote)

- Motor brand and efficiency class

- Gearbox and wheel assembly

- Paint/coating options for outdoor use

- Electrical panel design and safety logic

Technical Specifications Summary

Typical Configuration:

- Capacity: 1 to 30 Ton

- Span Range: Up to 25 meters

- Lifting Height: As per client request (standard 6–12 meters)

- Crane Travel Speed: 5 to 20 m/min (dual-speed optional)

- Hoist Type: Electric Wire Rope or Chain

- Power Supply: 3-phase, 415V, 50Hz

- Duty Class: M5/M7 (Medium to Heavy)

- Controls: Pendant, Radio Remote, or Cabin

Safety Standards & Quality Compliance

We prioritize operator safety and equipment reliability. All Konex semi gantry cranes comply with Indian and global safety benchmarks.

Standard Safety Features Include:

- Limit switches for over-travel protection

- Emergency stop buttons and brake systems

- Load limiters and thermal protection relays

- IS-standard structural design and load testing

- Overload prevention systems

- Optional anti-collision systems for multi-crane operations

- Earthing and short-circuit protection

IP55 protection for motors and panels

Common Challenges Solved by Semi Gantry Crane

Industrial buyers often face unique operational hurdles. Semi Gantry Cranes provide efficient solutions to many of these problems:

- Challenge: Limited overhead space or missing side runway

Solution: Single-leg design requires only one side of overhead support - Challenge: Tight budget for civil work and installation

Solution: Ground rail on one side reduces structural cost and complexity - Challenge: Handling materials in semi-open or outdoor settings

Solution: Designed for hybrid indoor-outdoor operations - Challenge: Irregular workspace with restricted bay access

Solution: Flexible movement along ground and rail axis