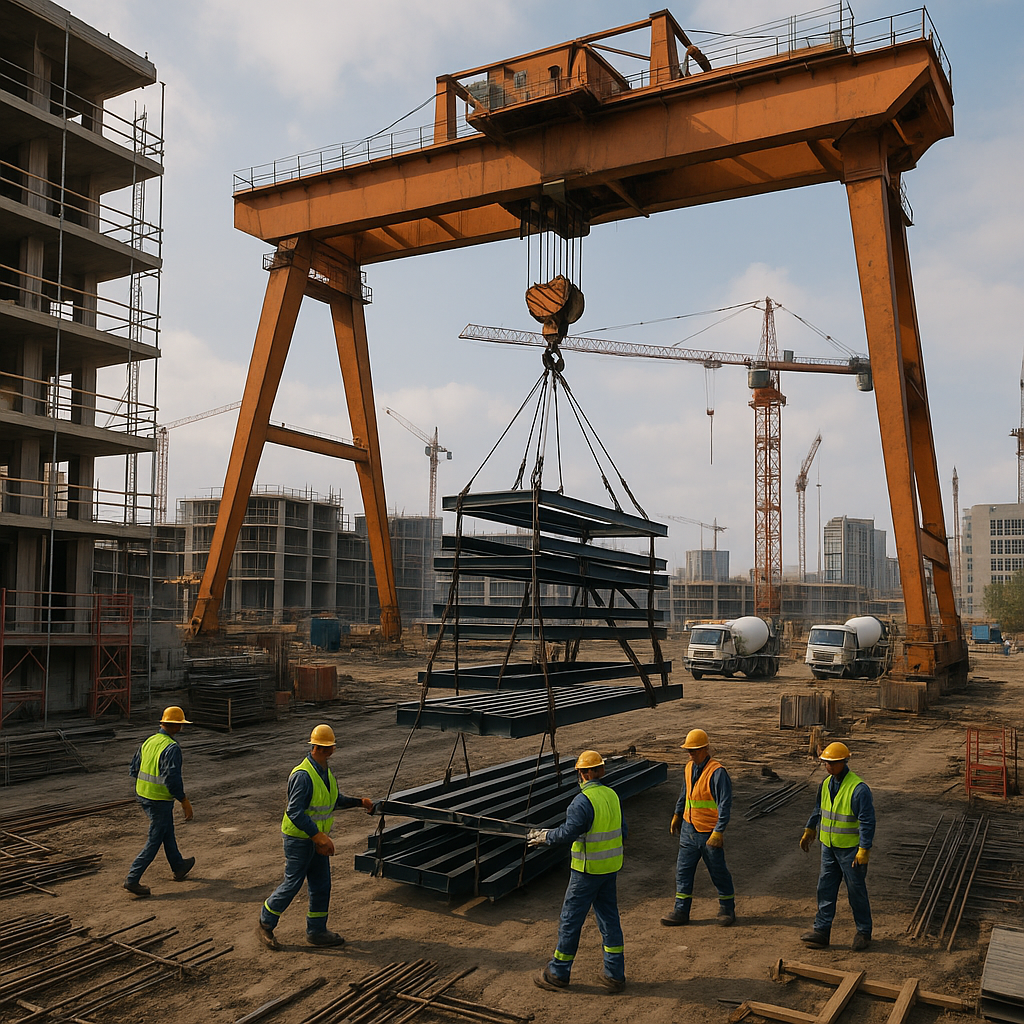

Gantry Cranes

Gantry Cranes are self-supporting cranes, meaning they don’t rely on any building structure for operation. Unlike overhead cranes that need beams or columns, gantry cranes stand on their own legs and move along a rail or wheels. This makes them highly versatile—suitable for both indoor and outdoor use, though especially preferred for outdoor environments such as yards, fabrication sites, and loading bays.

At Konex Material Handling Systems LLP, we offer gantry cranes in both Single Girder and Double Girder configurations, designed to match your lifting requirements precisely. With lifting capacities of up to 30 tons, our gantry cranes are widely used for moving light to heavy loads across industrial plants, construction zones, and logistics facilities. As a trusted Gantry Crane Manufacturer in India, we deliver reliable, durable, and fully customized solutions built to suit your operational needs.

Why Choose Gantry Cranes from Konex Material Handling Systems LLP

Konex brings deep industry knowledge and engineering expertise to every gantry crane we manufacture. Based in Ahmedabad, India, we serve industrial buyers with precision-built equipment backed by robust quality standards and on-time delivery. Every crane is fabricated using high-grade materials and modern production techniques, ensuring durability even in demanding work environments.

Our in-house design and engineering teams work closely with customers to create cranes that are not only functional but optimized for specific layouts and workflows. Whether you need a portable unit for field use or a heavy-duty system for a fabrication yard, Konex delivers solutions that are efficient, compliant, and future-ready.

Types of Gantry Cranes We Manufacture

Single Girder Gantry Crane

These cranes are built with a single beam and are ideal for lighter loads or limited headroom environments. Single girder gantry cranes are cost-effective, easier to install, and suitable for general-purpose applications. They are often used where moderate lifting capacities are required without compromising on mobility.

Double Girder Gantry Crane

For higher lifting capacities and longer spans, double girder gantry cranes are the preferred choice. Equipped with two parallel girders and a robust hoisting mechanism, these cranes are designed for handling heavy-duty operations in industries like steel processing, large-scale fabrication, or heavy equipment handling.

Semi-Gantry Crane

A semi-gantry crane combines the features of both overhead and gantry cranes. One side of the crane runs on an elevated rail (attached to a building), while the other side moves on the floor. This setup is ideal where partial support from the building is available, offering both structural efficiency and floor space optimization.

Heavy Duty Gantry Crane

Robust, powerful, and built for challenging environments—heavy duty gantry cranes are ideal for handling large, heavy loads in demanding industrial applications. Commonly found in shipyards, construction sites, and manufacturing plants, these cranes provide exceptional lifting capacity where permanent infrastructure may be limited or where flexibility in load handling is essential. Their primary advantage lies in their strength, durability, and ability to manage extreme lifting requirements efficiently.

Applications of Gantry Crane in Industry

Benefits of Using a Gantry Crane

- Self-supporting structure, no need for permanent building supports

- Versatile for both indoor and outdoor heavy-duty operations

- Can be relocated as needed, depending on project requirements

- Offers high lifting capacity without major structural modifications

- Ideal for demanding applications in large-scale or evolving industrial environments

What is a Heavy Duty Gantry Crane?

A Heavy Duty Gantry Crane is a large, robust lifting system engineered to handle exceptionally heavy loads in industrial settings. These cranes are designed for operations where strength, stability, and high lifting capacity are crucial—such as shipyards, steel plants, construction zones, and large manufacturing facilities.

Unlike lightweight or portable cranes, heavy duty gantry cranes are built for long-term, intensive use and can be equipped with advanced lifting mechanisms, motorized movement, and custom spans to suit large-scale applications. They are essential for industries requiring dependable, high-capacity lifting solutions with the flexibility to operate in areas without permanent overhead crane structures.

Customization & Manufacturing Capabilities

At Konex, we understand that no two industrial environments are the same. That’s why every gantry crane we manufacture is fully customizable. Our engineering team works closely with each customer to determine the ideal:

- Span length

- Height of lift

- Lifting capacity

- Rail or wheel configuration

- Material and finish specifications

All manufacturing takes place in India, at our facility in Ahmedabad, using quality-controlled processes that comply with IS and global standards. We ensure every gantry crane delivers consistent performance, even under heavy-duty usage.

Why Konex is a Trusted Gantry Crane Manufacturer in India

With 25+ of experience in the lifting equipment industry, Konex Material Handling Systems LLP has earned a reputation as a dependable Gantry Crane Manufacturer in India. Our factory is equipped with modern fabrication and testing facilities, and our qualified engineering team ensures each project meets technical precision and operational safety.

We use only proven components from reliable suppliers and focus on long-term value for our customers. Whether you’re a small workshop or a large manufacturing unit, we provide cranes that integrate seamlessly into your operations and support sustained productivity.

Gantry Crane Safety and Compliance

Safety is at the core of every gantry crane we produce. Our systems are fitted with essential safety features to protect operators and equipment alike. These include:

- Overload protection systems

- Anti-collision devices

- Limit switches for hoisting and travel

- Advanced braking systems

- Compliance with Indian IS standards and relevant codes

Routine checks, maintenance guidelines, and user manuals are provided with every unit to ensure safe and efficient operation across its lifecycle.

Choosing the Right Gantry Crane

Selecting the right gantry crane depends on a range of operational and environmental factors. Start by assessing your lifting capacity requirements—what weight will you need to lift regularly, and how often? Then, consider the working environment: is it indoors, outdoors, or a combination?

For heavy industrial tasks that involve consistent, high-capacity lifting, a heavy duty gantry crane is the ideal choice. These cranes are engineered for strength and durability, making them suitable for large-scale applications such as shipbuilding, fabrication yards, and infrastructure projects. The layout of your facility also matters—especially ceiling height, floor conditions, and available space.

Finally, factor in the frequency of usage: high-cycle operations demand robust, feature-rich systems designed to withstand continuous use. Our experts at Konex are always available to help you assess these factors and recommend the most suitable gantry crane for your application.

Contact Konex for Gantry Crane Solutions

Whether you’re expanding your manufacturing facility, upgrading your logistics yard, or setting up a new fabrication line, Konex has the right gantry crane solution for you.

Reach out to our team for a tailored quote, site assessment, or technical support. With our combination of engineering strength, manufacturing expertise, and customer-first approach, we’re here to move your operations forward—safely, reliably, and efficiently.